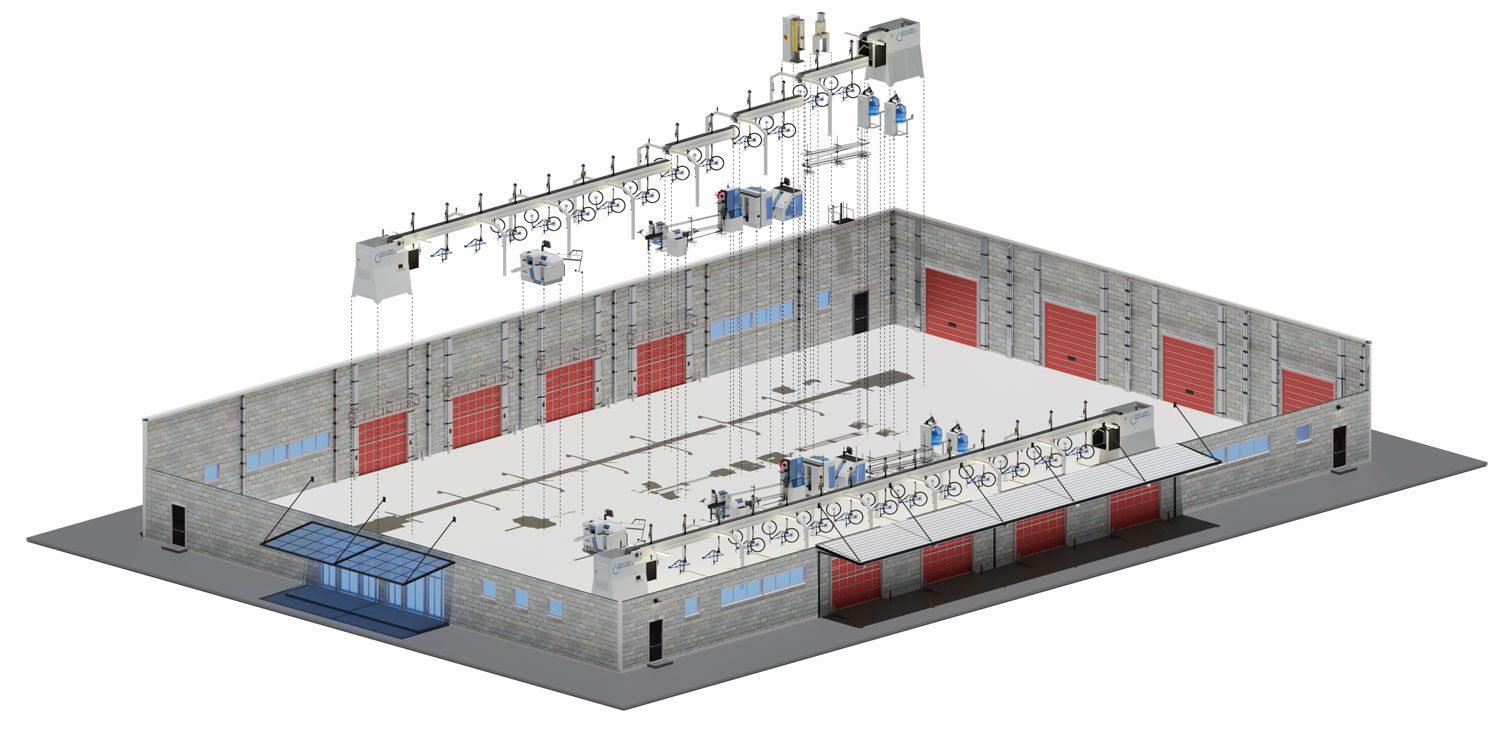

Scalable Machine lines

Every company has its own desired wheel production output, therefor Holland Mechanics has specialised itself in offering different customisable lines to meet the needs and wants of the client. With careful coöperation we can give advise for the best combinations machines. The pyramid shows different stages, each stage down the line represents a greater volume output.

Feel free to contact us for more information about the layout solutions we offer.

From Start-up to Full line

启动自行车车轮生产线

A Lacing/Tightening machine combined with a Pro Truer or Villum. This start-up combination is highly efficient for the smaller wheel manufacturers.

Line consists out of: 1× Lacer 1× SMT/Villum

Efficiency: Lacing & Tightening process: 60 – 70 seconds

Quality: Optional Nipple Washer Feature for customised QLet fitting

BUDGET line

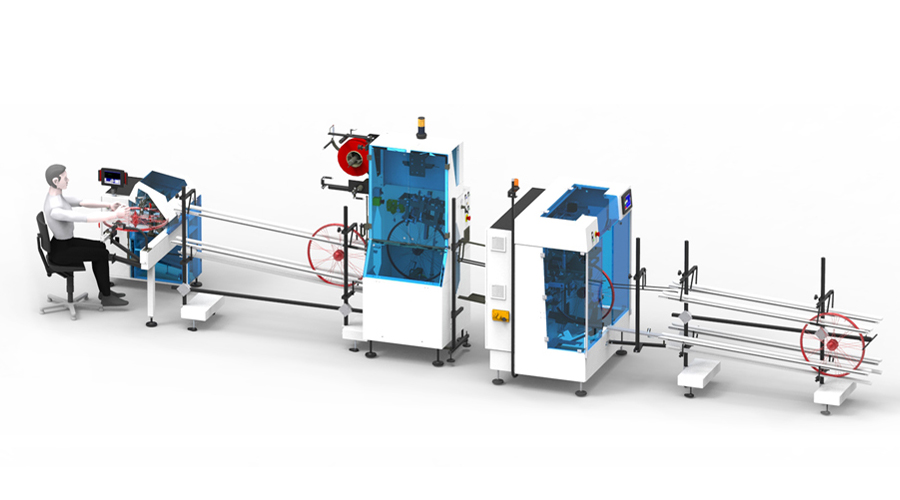

A Lacing/Tightening machine combined with an automatic truing robot. This line is the core of a mass production line. From this combination on you can expand to endless combinations.

Line consists out of : 1× Lacer 1 × Robot

Efficiency: Up to 350 wheels per 8 hour shift

Quality: Constant quality output

基础自行车车轮生产线

A Lacing/Tightening machine followed up by a Rim Taper and a Truing Robot. The Rim Taper tapes the rims and is also capable of stabilizing the just laced wheel for optimum quality output. When using a Robot OT, the Rim Taper comes after the truing process since the spoke holes have to be open.

Line consists out of: 1× Lacer 1× HT 1× Robot

Efficiency: Rim taper for different wheel sizes

Quality: Optional stabilizing and self-adhesive rim tape

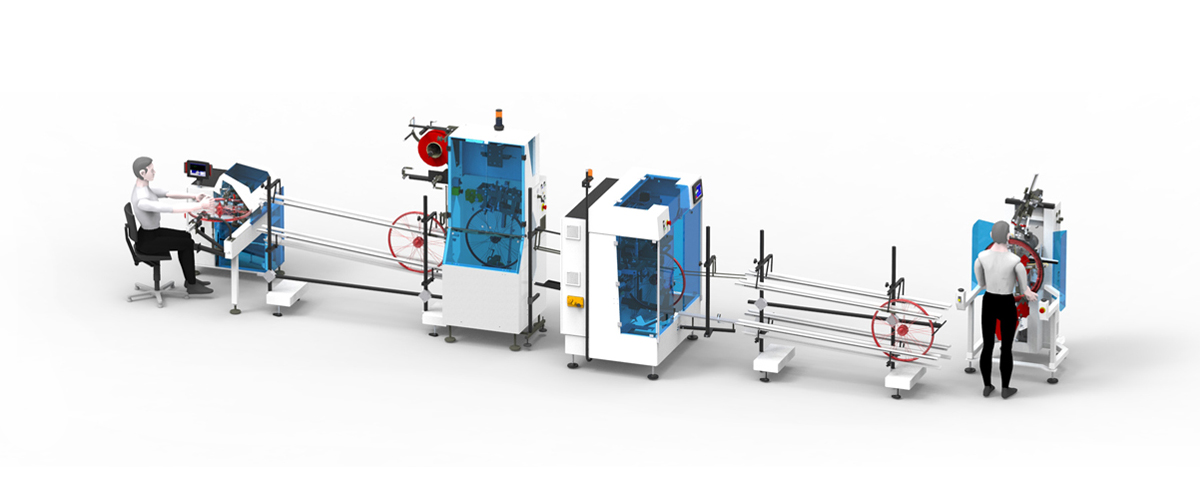

COMPLETE line

A Lacing/Tightening machine followed up by a Rim Taper and a Robot. The Rim Taper tapes the rims and is also capable of stabilizing the just laced wheel for optimum quality output. A Tyre Mounting Console is placed at the end of the line for the finishing touch, this is exceptionally useful and time saving for manufacturers whom produce complete bikes.

Line consists out of: 1× Lacer 1× Rim Taper 1× Robot 1× TMC

Efficiency: time savings during tyre fitting

Quality: Optional stabilizing and self-adhesive rim tape + tyre fitting

ADVANCED line

By introducing a second lacer and a Robot Quattro production time increases to approximately 80 wheels per hour. The Robot Quattro ensures that the tightening process is speed up with 4 nipple hands so that the truing robot takes less time to true the wheel.

Line: 2× Lacer 1× Rim Taper 1× Quattro 1× Robot 1× TMC

Efficiency: Second lacer and Robot Quattro increases production up to 650 wheels per 8 hour shift

Quality: During the stabilizing process every nipple is automatically locked for extra quality and wheel-safety

Premium Line

The Quickest way of producing a wheel is by introducing a Hub Filling Station to the line. By automating hub filling with a fast flow to the lacers, wheels are made in no time, followed up by the Rim Taper, Robots and Tyre Mounting Console. It is possible to supply 2 lines of lacers and robots with one Hub Filling Station for massive output.

Line: 1× HFS 2× Lacer 1× Rim Taper 1× Quattro 1× Robot 1× TMC

Efficiency: Decreases labour cost of filling hubs by hand

Quality: Hub filling ± 30 seconds per hub