Partnership & Service

At Holland Mechanics, our commitment extends beyond mere product offerings. We are dedicated to forging enduring partnerships that elevate your production capabilities. Our primary objective is to provide unwavering support to our customers, enabling them to harness the full potential of our machinery for superior bicycle manufacturing.

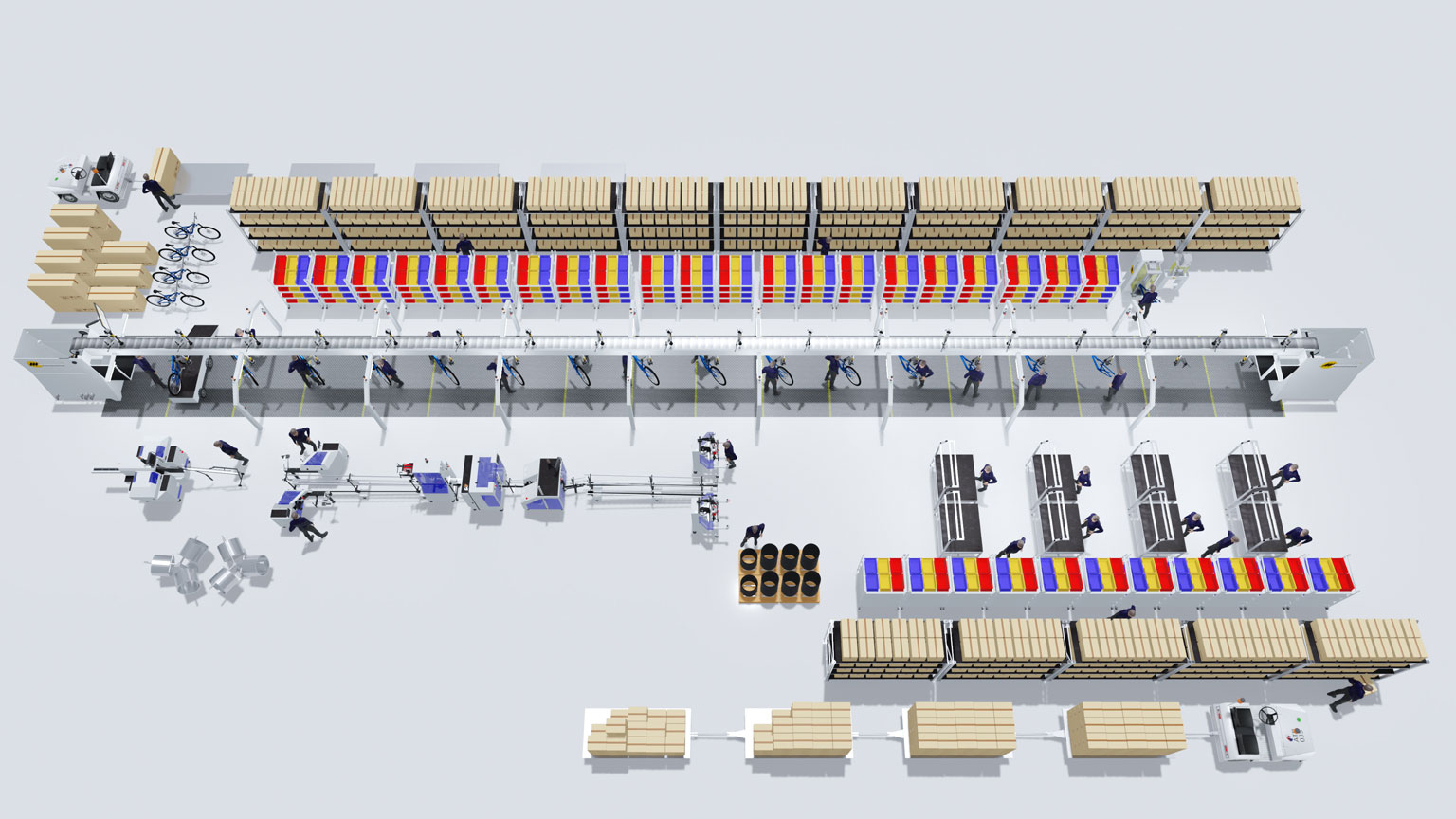

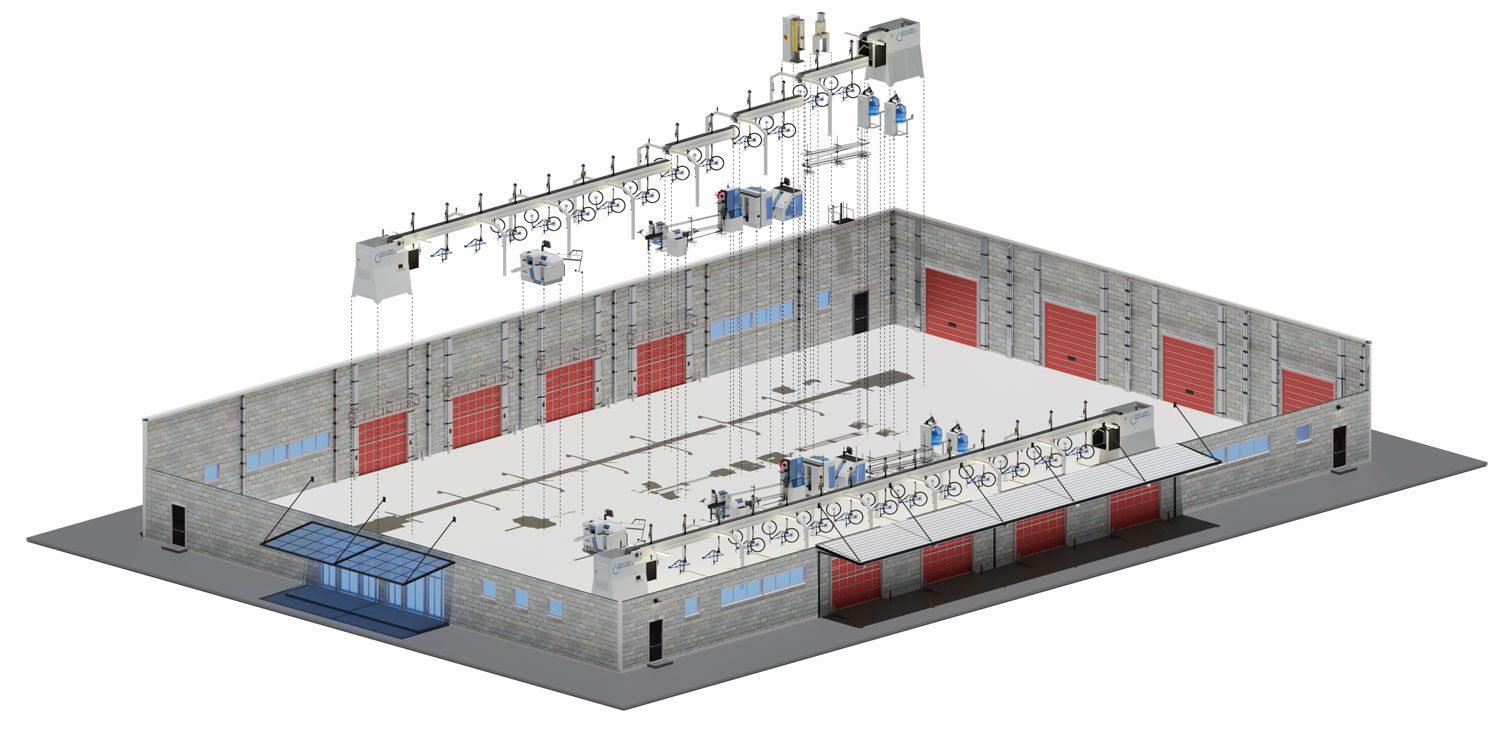

Our services are nothing short of exceptional. For more information, please refer to our service section. Additionally, we are dedicated to ensuring that our customers’ operations run with the utmost efficiency. To facilitate this, we can create 3D layouts tailored to your specific needs and offer expert advice on optimising tact-time. This guarantees a seamlessly smooth operation and offers valuable insights into the optimal placement of our machines.

Turn-key Factory

We can help you create the perfect factory, Combining both wheel and assembly machinery. For a accurate, ergonomic and efficient factory line.

BETTER EFFICIENCY AND QUALITY WITH SYNCHRONIZED TURNKEY ASSEMBLY SOLUTIONS

At Holland Mechanics, we’re at the forefront of revolutionising the e-bike and bicycle industry, and we’re thrilled to share our journey with you. Reshoring, a strategic shift bringing production closer to the market, has become a prominent theme in Europe and North America’s e-bike, bicycle, and component industry. This transformative shift not only impacts assemblers but also compels components manufacturers to reevaluate their business models.

The Complexity Challenge

The e-bike, with its increasing complexity compared to regular bicycles, has introduced longer production times and the necessity for frequent quality checks. This dynamic landscape is driving the industry towards more efficient, intelligent, and adaptable production processes. However, implementing lean processes in traditional bicycle factories presents its set of challenges.

Our Evolution and Integration

Holland Mechanics, renowned for its advanced wheel building machinery and extensive industry network, has transformed into a comprehensive supplier of bicycle production machinery. In 2019, we embarked on an integration journey with our Italian partner, Marchetti, to create an ecosystem that would cater to the industry’s evolving needs. This integration is now a reality, allowing Holland Mechanics to offer a seamless, integrated, and lean assembly process. Our flexibility to swiftly adapt and develop new tools or machinery is one of our strengths. We understand that service is paramount, which is why we provide comprehensive support, including preventive and predictive maintenance, and an online spare parts service. Our goal is to enhance continuity and minimize production disruptions for our valued customers.

Our Comprehensive Solutions

Today, Holland Mechanics stands as your go-to partner for turn-key solutions in e-bike and bicycle assembly. Our product portfolio encompasses everything you need, except for painting. From pre-assembly tools to robotised wheel building machinery, and our flagship product, the Airline system, we’ve got your production needs covered. The Airline system, with its motor-driven hanging assembly conveyor, streamlines your assembly and wheel building processes in a synchronised production flow. It’s designed to provide clean floor space and ergonomic advantages for your team. Plus, it offers the flexibility to handle various bicycle types with ease.

The Human Touch

While automation is prevalent in many production processes, our e-bike assembly line remains manual. Why? The complexity and variety of components demand the flexibility that human hands provide, ensuring efficiency without compromising on quality. Collaborating with Lean Specialists, our users have achieved remarkable efficiency gains of over 30% with our scalable Airline system.

In Conclusion

Holland Mechanics is not just a company; we’re your partner in reshoring and elevating production efficiency in the e-bike and bicycle industry. Our integrated solutions are engineered to streamline your assembly processes, elevate quality, and drive industry growth. Join us in shaping the future of this dynamic industry.

ROADMAP FOR GROWTH

Allow us to unveil your limitless potential, supercharge your production for sustained growth, and pave the way for your transformation into a self-sustaining manufacturing powerhouse

BUILD MODULAR AND EXTREMELY FLEXIBLE, A PERFECT FIT FOR EVERY BICYCLE FACTORY

Holland Mechanics, as a key player in the bicycle industry, places a strong emphasis on flexibility in production. This flexibility is vital to ensure product availability, especially during peak seasons when manufacturing needs to be rapidly scaled up. Additionally, to accommodate the market’s structural growth, their existing facilities are designed for easy scalability of production capacity. They offer turn-key solutions for e-bike and bicycle assembly, with the exception of painting.

In the modern bicycle production landscape, modular factories have become the industry standard. These facilities are designed to handle market fluctuations with minimal additional costs, offering flexibility in layout and scalability. Holland Mechanics adopts a linear design approach, which reduces space consumption, simplifies maintenance, and provides flexibility and scalability. The fishbone construction allows for component supply from either side, enhancing production flexibility along the assembly line.

The trend of reshoring bicycle and e-bike assembly to Europe is gaining momentum. This shift allows assemblers to respond rapidly to demand fluctuations and cater to on-demand production based on customer specifications. Flexibility in production layout is crucial for this transition.

Holland Mechanics has integrated artificial intelligence (AI) into wheel production. AI algorithms optimize spoke tension, reducing production time and enabling precise coordination between wheel building and bicycle assembly, regardless of complexity.

They have also developed a dedicated assembly line for cargo bikes, addressing challenges posed by the size of these products. Synchronized assembly systems allow for simultaneous handling of front and rear sections.

The rise of e-bikes in Europe has accelerated the adoption of Industry 4.0 production. Increased investment budgets have enabled automation on an unprecedented scale, facilitating enhanced quality control at various stages of production, a departure from the traditional end-of-line quality control.

In summary, Holland Mechanics prioritizes flexibility in production, adopting modular designs and leveraging AI to optimize efficiency and quality control. Their commitment to meeting industry trends, such as reshoring and Industry 4.0, positions them as a leading supplier in the bicycle and e-bike assembly solutions market.

DESIRED CAPACITY

DESIRED CAPACITY

In the world of bicycle manufacturing, the desired capacity and efficient mechanics play a vital role in determining the machinery required for processing components and assembling bicycles. Holland Mechanics offers expertise when it comes to choosing the appropriate machinery where several factors come into play. First and foremost is the desired capacity of the factory. Manufacturers should consider utilizing a transition year like 2023 to streamline their production layout. This information is crucial in identifying the machinery’s capabilities and ensuring that it can meet production requirements effectively.

Available space

Available space

Having an efficient factory layout design is crucial for achieving optimal productivity, reduction of cost, and overall operational performance. Holland Mechanics, renowned for its expertise in industrial engineering, provides valuable customized advice that takes into account your specific requirements and available space. By considering factors such as desired output, space utilization, and workflow optimization, Holland Mechanics assists you in creating a factory layout that maximizes efficiency and aligns with your business goals. If you’re operating a bicycle factory, you can share the 2D building dimensions available to Holland Mechanics, and they will explore the best way to utilize the space effectively.

Concept design

Concept design

Holland Mechanics revolutionizes factory layout design by working closely with clients to generate realistic 3D environments that accurately depict space and equipment requirements. By embracing advanced technology and utilizing advanced software and modeling tools, they provide a tangible representation of the factory’s layout, allowing for optimal equipment placement, efficient material flow, and maximum productivity. With this expertise, businesses can visualize, optimize, and fine-tune their factory layouts before implementation, ensuring operational success. Embrace the power of 3D modeling and take your factory layout design to new heights with Holland Mechanics equipment.

Roadmap for growth

Roadmap for growth

Holland Mechanics goes the extra mile by proposing a growth roadmap that aligns relevant equipment investments with strategic timelines. By understanding clients’ growth objectives, assessing production capacity, and strategically selecting equipment, they create a comprehensive plan that optimizes expansion efforts. With a detailed timeline in place, businesses can strategically deploy capital investments, optimize ROI, and navigate their growth journey effectively. Holland Mechanics stands as a reliable partner, providing the expertise and guidance needed to achieve long-term success in an ever-evolving industrial landscape.

Interested in what a full factory may look like?

Try Explore bike-making in 3D, dive into our factory now!