Solutions

At Holland Mechanics, our relentless pursuit is to empower our partners with cutting-edge wheel building solutions and assembly solutions.

From crafting precision-engineered wheels for carbon enthusiasts to rugged, high-performance options for fat tires, eBikes, motors, and even specialized wheelchair wheels, there is no spoked wheel our state-of-the-art solutions cannot produce – regardless of size or complexity.

From scalability & special spokes to increase your productivity. Explore the diverse array of solutions we offer and unlock the potential to enhance your production efficiency.

Scalable Solutions & Options

At Holland Mechanics, we understand that every company has unique requirements when it comes to wheel production. That’s why we’ve dedicated ourselves to providing a diverse range of customizable production lines, tailored to meet our clients’ specific needs and preferences. Through collaborative partnership, we can offer expert advice on the optimal machine combinations that suit your goals.

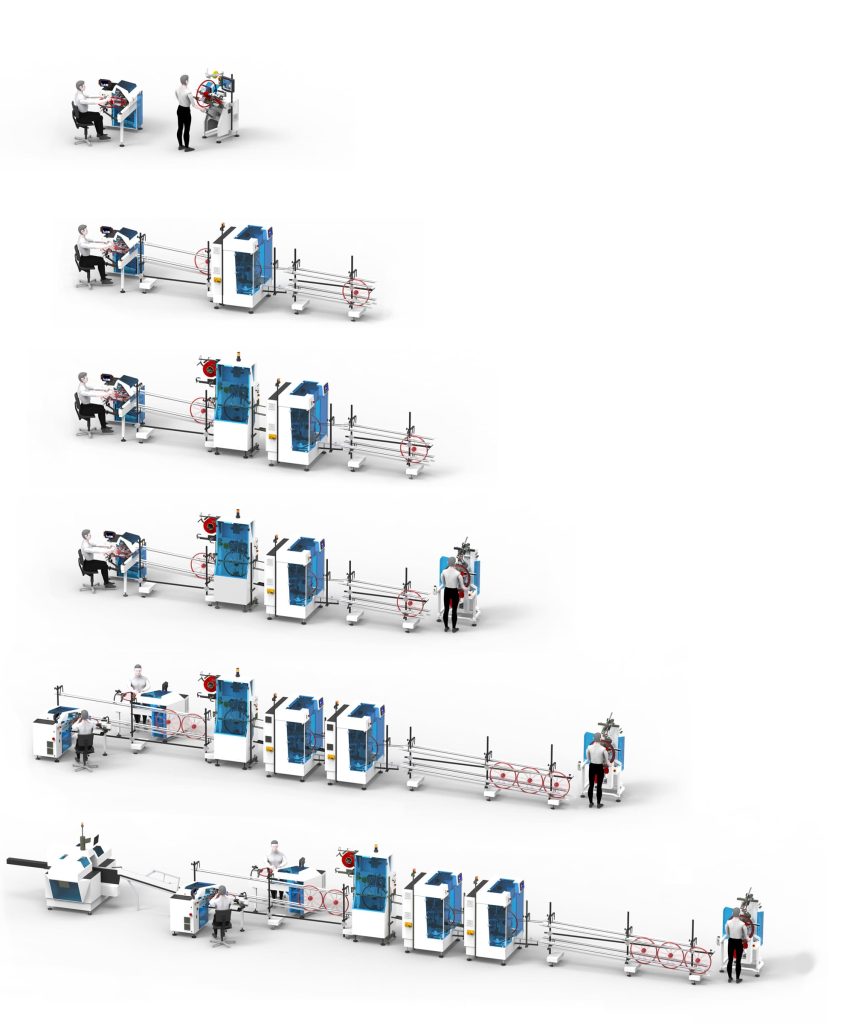

Our Production Pyramid illustrates various stages, each symbolizing an increase in production volume capacity, ensuring your scalability needs are met.

Don’t hesitate to reach out to us for more in-depth information about our tailored layout solutions. Discover how Holland Mechanics can help you elevate your production capabilities and achieve your vision.

Scalable from:

- Start-up line

- Budget line

- Basic line

- Complete line

- Advanced line

- premium line

TCS-spoke technology

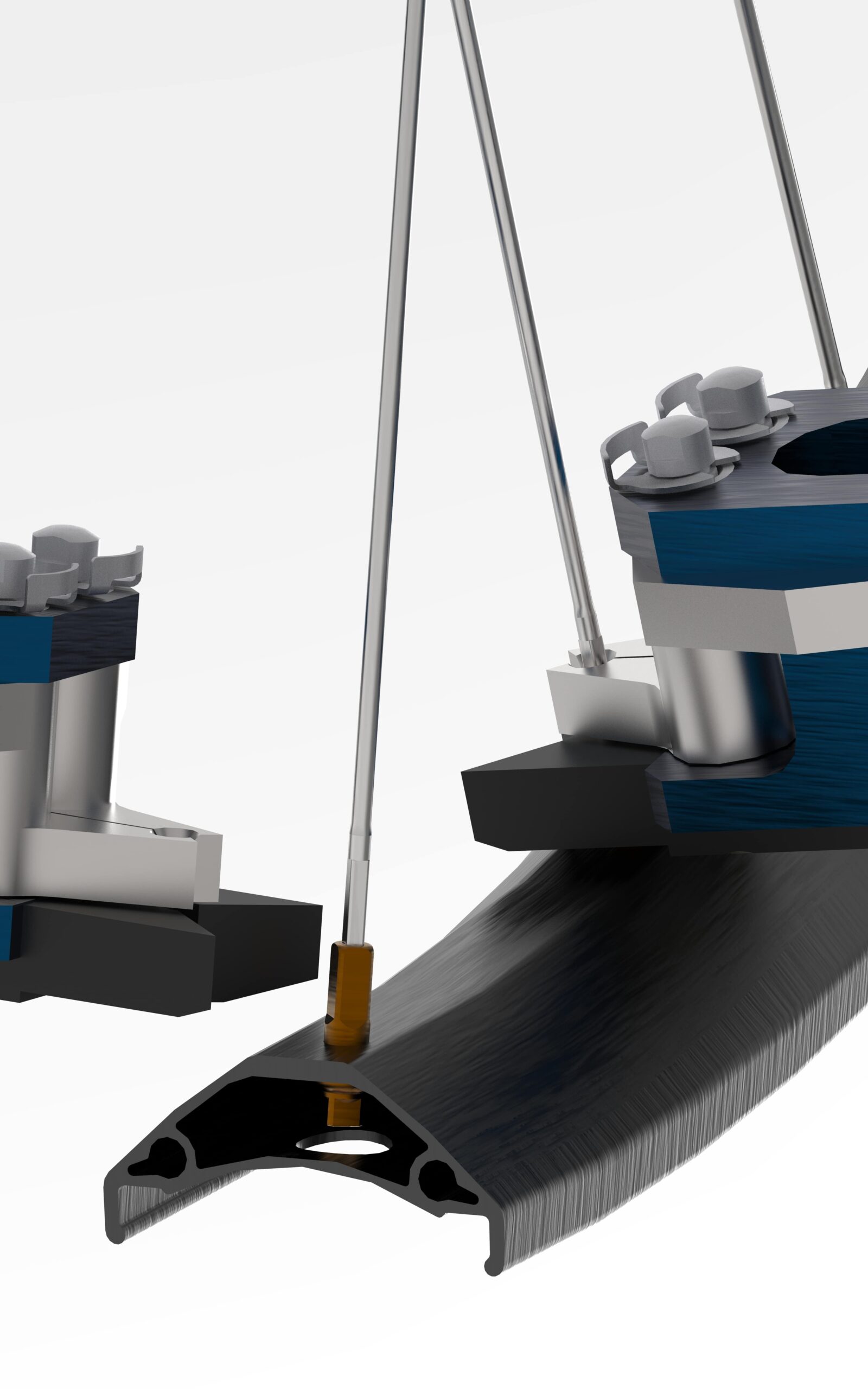

TCS square spoke gripping area :

TCS spokes are a patented technology by Holland Mechanics. These spokes are designed to prevent torsion during the lacing and truing process by holding the square section of the spoke.

Our advanced spoke grippers are designed to securely hold the square section. These grippers can be found on our lacers and the Robot-OT, delivering precise and consistent results. The outcome? Perfectly crafted wheels that combine exceptional quality with unmatched durability.

This cutting-edge technology is ideal for straight-pull spokes, making it the go-to solution for modern wheel builders who demand performance and reliability. Plus, our TCS spokes are available from three industry-leading manufacturers:Sapim, Alpina and DT-Swiss.

Choose our spoke grippers in combination with the TCS spokes to elevate your wheel-building process. Experience the perfect blend of innovation and excellence, creating wheels ready to perform at the highest level and delight your customers with reliability and precision!

More information on the benefits, click on more info!

Aluminium & eBike

Tailoring Aluminum & eBike Wheels to Every Production Capacity

At Holland Mechanics, our machines are engineered to craft impeccable standard aluminum & eBike wheels. The beauty of our technology lies in its scalability – it’s all about tailoring the output to match your desired wheel production rate.

For a deeper dive into optimizing your wheel production, don’t hesitate to get in touch with us. Discover how Holland Mechanics can elevate your wheel-building capabilities to new heights.

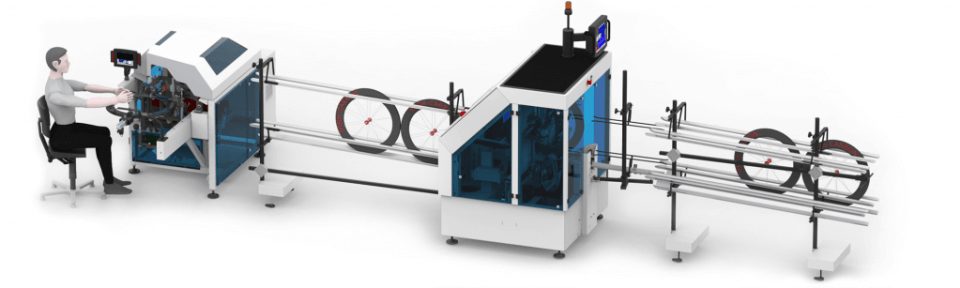

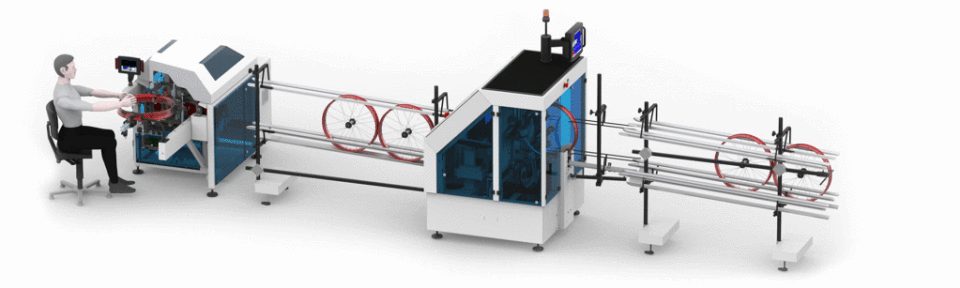

eBike wheel solutions examples

DESCRIPTION

The Holland Mechanics E-Bike solution is especially made to handle all possible E-bike wheels. The Intelligent Single Lacer is fully automatic adjustable to any E-Bike wheel. However, when producing E-bike wheels with rather big hubs we advice an Inline Lacer to adjust to the large spoke angles. In Combination with the Robot SG which is capable of handling all E-bike wheels. Holland Mechanics has developed special features like actuators and ACCU which makes it easier to true the E-wheels. One of the latest E-wheel option is the Wire Catcher, whereby the robot can handle hubs with a wire coming out of the axle.

Depending on the components used, the combination of the Inline lacer and the SG robot can result in greater efficiency. The Inline lacer is capable of screwing the nipple of the spokes, both axial and radial into the wheel. This means that even with large angles, which are common in larger wheel hubs, the Inline lacer can still securely fasten the spoke nipples.

On the other hand, the SG robot is better suited for wheels with larger hubs due to its versatility. It offers multiple options and can automatically scan the wheel. This is particularly useful when dealing with different types of wheels that pass through the production line. The SG robot can adapt and work efficiently with various wheel configurations.

For individuals seeking a production line that prioritizes speed over versatility, we introduce the Intelligent Single Lacer (ISL) and Robot DTI. The ISL stands out as a popular choice due to its ability to accommodate various spoke designs and its ease of changeover between different setups.

While, the Robot DTI is the ultimate choice for those in need of the fastest wheel truing machine. If you require a production line that emphasizes both speed and high-quality wheel output, the Robot DTI may be the preferred option for your specific needs.

Carbon

Craft carbon wheels of unparalleled quality, surpassing human capabilities.

At Holland Mechanics, we’ve harnessed cutting-edge machinery specifically designed for crafting top-notch carbon wheels. Our state-of-the-art machines possess capabilities beyond human capacity, allowing us to create impeccably stable and high-quality carbon wheels. These machines can be tailored to match your desired production rate, ensuring efficiency and precision.

If you’re interested in delving deeper into optimizing your carbon wheel production or even mixed wheel production, we invite you to reach out to us. Discover how Holland Mechanics can elevate your wheel-building capabilities to unprecedented levels of excellence.

DESCRIPTION

The Holland Mechanics Carbon solution is purpose-built to accommodate a wide range of carbon wheels, regardless of their height and width. Our machines are versatile and can be customized with various settings to align with your specific requirements.

We suggest two primary machine lines for carbon wheels, depending on the components involved. If you’re working with wider rims, we recommend using the OT robot due to the need for greater angles to ensure optimal nipple contact. For more advanced production lines and inquiries, we encourage you to get in touch with us directly. For an example of a carbon proLine, have a look at the video.

The pairing of an Inline Lacer Pro and a Robot OT-Pro offers unparalleled flexibility in crafting various wheel shapes. This solution excels in accommodating carbon rims of varying heights, thanks to its ability to tilt and adjust the screw head for optimal nipple contact in angle-drilled spoke holes. The Robot OT-Pro seamlessly transitions with a maximum rim height of 90mm and precision up to 0.1mm. These machines are specially designed to complement each other, aiming to achieve the highest possible quality output.

The Holland Mechanics High-End Rim Drilling Station is engineered to perfection, ensuring precise and consistent drilling for carbon wheels. With advanced technology and meticulous attention to detail, this equipment sets a new standard for precision in rim production. Say goodbye to variations and imperfections – our drilling station guarantees uniformity in every wheel. We also have a rim configurator for easy use available.

FAT

Create top-notch Fat wheels, achieving a level of quality and simplicity that exceeds human capabilities.

At Holland Mechanics, we’ve harnessed cutting-edge machinery uniquely tailored for crafting premium Fat-bike wheels. Leveraging our expertise and experience, we’ve developed equipment capable of handling a wide range of fat wheel types. Our commitment to quality guarantees results that surpass manual craftsmanship, with the ability to accommodate Fat-bike wheels up to 100mm in width.

We excel in producing high-quality Fat-bike wheels efficiently and swiftly and invite you to have a look for yourself what our machines can produce.

DESCRIPTION

The Holland Mechanics Fat solution is tailor-made to handle a diverse array of fat wheels, accommodating varying heights and widths with ease. Our machines offer versatility and can be fine-tuned with a range of settings to precisely align with your specific needs.

We recommend two primary machine lines for Fat bikes, depending on the components involved. If you’re dealing with wider rims featuring substantial hubs, we recommend employing the IL-X and OT-X robot due to their ability to provide the necessary angles for optimal nipple contact. For high-output requirements, the SL and Robot DD are our top recommendations.

The Inline Lacer X (IL-X) is meticulously crafted for the assembly of high-quality wheel components. With the ability to lace angled drilled rims up to 100mm wide, the IL-X serves as a versatile ‘all-rounder’ capable of handling various rim sizes seamlessly. It even accommodates popular disc-brake rims without the risk of sticker scratching.

Additionally, the IL-X can be seamlessly integrated with the Robot OT-X. This powerful combination enables fully automated truing for all wheels produced by the IL-X, spanning from regular 35mm wide rims to those as wide as 100mm.

The pairing of the Single Lacer X (SL-X) and the Robot DD-X is specifically engineered to handle extremely wide rims, reaching up to 100mm in width. This versatile SL-X accommodates customers with straight-drilled rims, while its rim-driving unit has been upgraded to cater to disc-brake rims with stickers, preventing any risk of scratching.

When used in tandem with the DC-X Robot, which is also optimized for wide rims, production times are significantly reduced, resulting in substantial cost savings on labor.

WHEELCHAIR

Create high grade wheelchair wheels, achieving high quality solid wheels in just a matter of seconds.

At Holland Mechanics, innovation is at the heart of everything we do. We’ve taken on the challenge of crafting solid wheels for wheelchairs, and our relentless pursuit of excellence has led us to perfection. Our cutting-edge machines are purpose-built to create flawless solid wheels, and we’ve gone a step further by designing a specialised tyre fitter exclusively for wheelchairs.

If you’re eager to explore how Holland Mechanics can elevate your wheelchair needs, don’t hesitate to reach out to us. Discover the future of wheelchair mobility with us today

The ideal machine combination for wheelchair wheel assembly is the Intelligent Single Lacer paired with the DTI system. These machines can be customized with specific options to seamlessly adapt to the unique requirements of wheelchair wheel assembly. Wheelchair wheels typically feature a push bar, prompting Holland Mechanics to engineer specialized nipple hands that can avoid contact with the bar while reaching the nipple. By implementing this approach, not only is assembly time reduced, but the entire vertical wheel assembly process is significantly enhanced.

Solid Tyre fitter

Solid tyre fitter

Specially made for solid tyres, great for wheelchair wheels and easy in use

MOTOR

Crafting top-notch spoked motor wheels, achieving exceptional quality motor wheel solutions in a matter of seconds.

At Holland Mechanics, innovation is the driving force behind all of our endeavours. We’ve taken on the mission of crafting top-tier spoked motorcycle wheels for motors, and our unwavering commitment to excellence has led us to achieve perfection. Our state-of-the-art machinery is meticulously designed to produce flawless spoked motor wheels. Furthermore, we’ve pioneered specialized truing robots exclusively tailored for motor applications.

If you’re enthusiastic about experiencing how Holland Mechanics can elevate your motor wheel requirements, please don’t hesitate to get in touch with us. Discover the future of motorcycle spoked wheels with us.

Holland Mechanics has introduced the world’s first comprehensive solution for motorcycle wheel machining. The MIL initiates the wheel-building process, equipped with automatic change-over and a versatile screw head for swift lacing of various wheels.

The MS stabilizer follows, evenly distributing tension and reinforcing components. The MQ and MT then take over, using advanced algorithms and precision measurements to ensure each wheel exits the production line perfectly tensioned and trued, setting industry-leading speed standards.

RIM

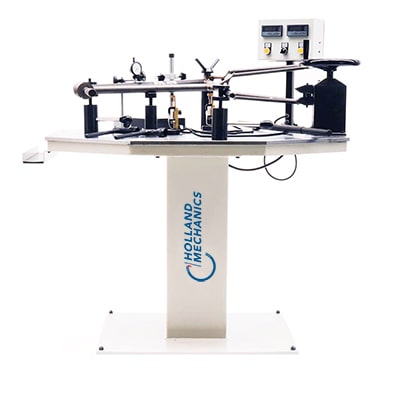

At holland mechanics you can also start producing your own rims, with our rim production line.

Holland Mechanics has listened to the requests of our customers who desire the ability to manufacture standard aluminum rims themselves to reduce expenses. With our innovative rim production line, the investment pays for itself within a few years, resulting in substantial cost savings, including reduced labor expenses, thanks to the automated rim production process.

Our cutting-edge machinery line is fully equipped to craft aluminum rims from aluminum profiles. This process involves precision bending, cutting, pinning, and hole punching/drilling to create rims. Our machinery is capable of producing rims ranging from 20″ to 29″ in size.

Want to make aluminium rims yourself

AUTOMATIC vs MANUAL

Holland Mechanics offers two types of rim production solutions. Either fully automatic or manual. The main difference is the amount of operators. the manual line exist of 4 different stations, whereby each station needs an operator.

The fully automatic line is a 3-step process and doesn’t require any operators. The rim profile is turned into a coil that automatically transports through the machines.

Automatic rim line machines

Rim bendING

Automatically loads profile from supply table and bend aluminium rim in 3 coils

Rim bendING

Automatically loads profile from supply table and bend aluminium rim in 3 coils

Manual rim line machines

ASSEMBLY

Holland mechanics also provide pre- and Assembly machinery for a full factory design!

At Holland Mechanics, we’re more than just machinery for wheels; we’re your source for advanced assembly machinery as well. Our range of Assembly machines goes beyond the ordinary, creating a comprehensive factory environment that optimizes your production process.

Our machinery empowers manufacturers to bring certain components in-house, such as chains and brake sleeves, while streamlining labor-intensive tasks like fitting fork cups. Explore our thoughtfully curated selection to witness firsthand how we can enhance your production capabilities. See the assembly machinery first hand.

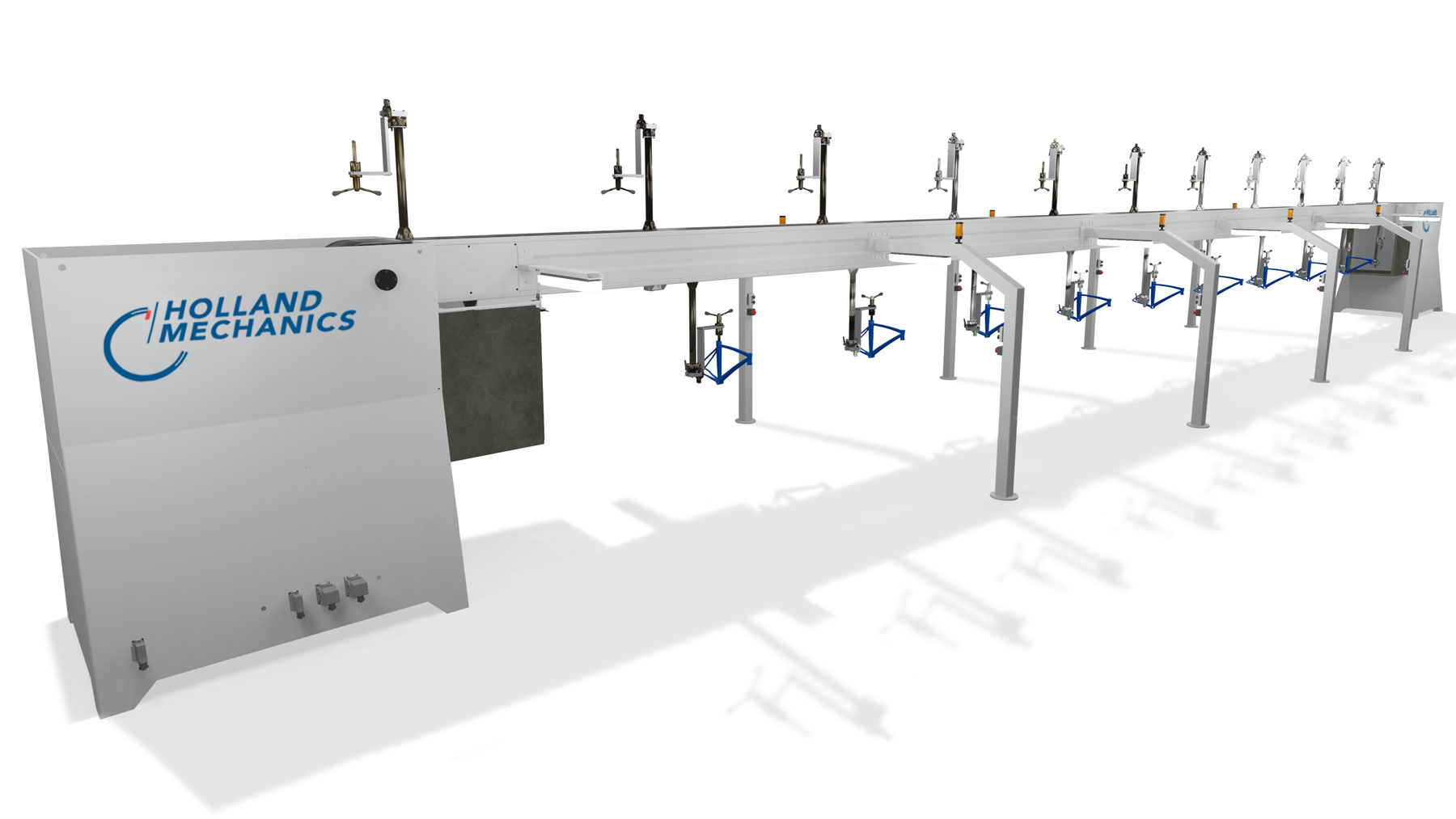

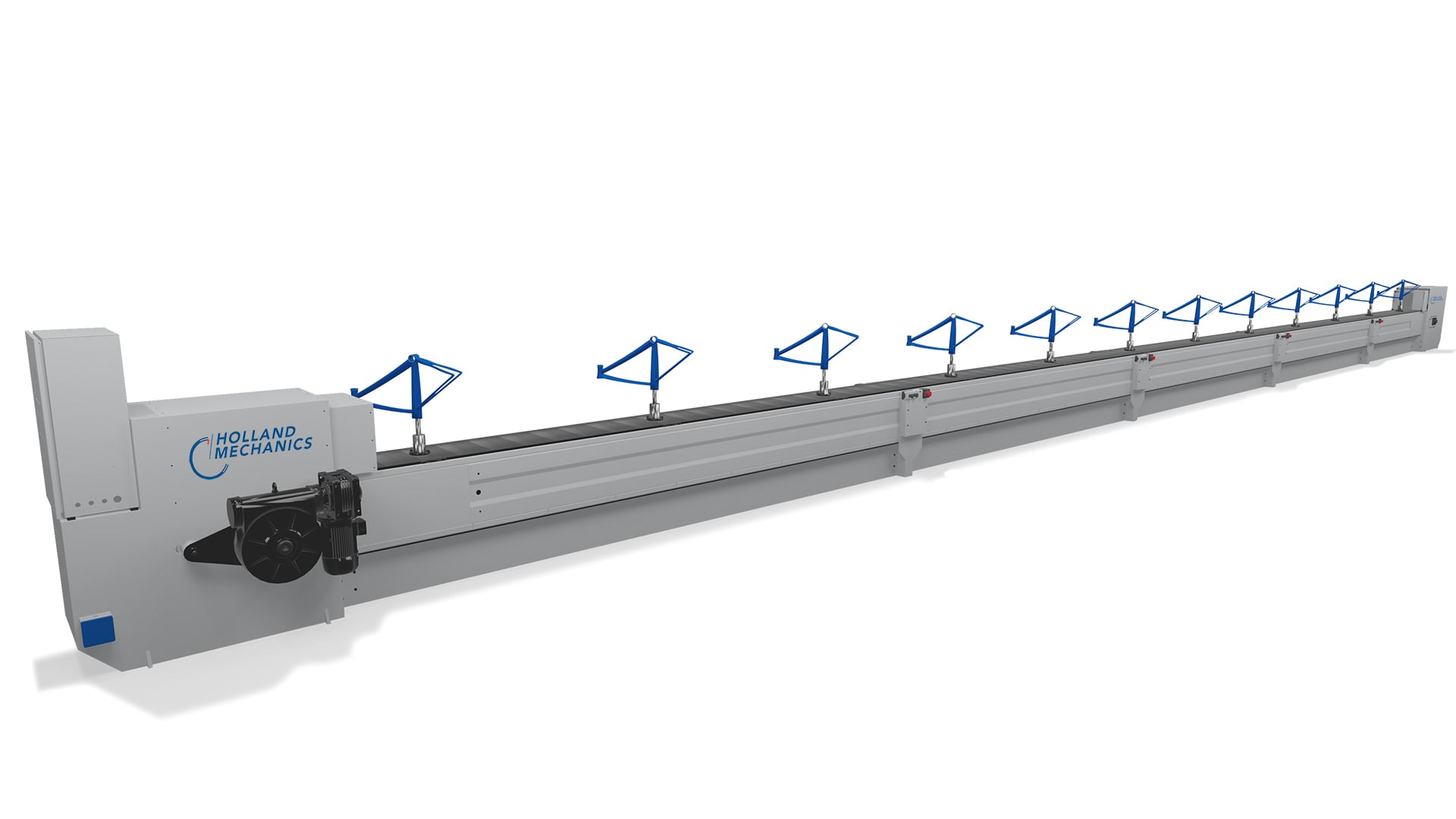

Bicycle Assembly machinery

The Airline is a motor driven Assembly conveyor line. The conveyor can move on different speeds or stand still for an optimal working environment. Operators have the freedom to move around the assembly area to access various bicycle components, ensuring ergonomic efficiency. The airline can be made on any length, this makes it ideal because that means it can be placed in any factory without any structural modifications.

The Floorline is a motor driven Assembly conveyor line and is the budget version of the Airline. The conveyor can move on different speeds or stand still for an optimal working environment. Operators have the freedom to move around the assembly area on one side, and can turn the bicycle in 360 degrees, ensuring ergonomic efficiency. The floorline can be made on any length, this makes it ideal because that means it can be placed in any factory without any structural modifications.

Bicycle pre-Assembly machinery

Bicycle frame preparation machinery

BOTTOM BRACKET MACHINE

a reaming, threading and facing system that can widen the tube, apply threading and face of any edge for a clean finish on the bottom bracket of the frame

Headset tube MACHINE

a reaming system that widens the tube to make head cups, steering wheel, and forks fit perfectly onto the frame

BOTTOM BRACKET MACHINE

a reaming, threading and facing system that can widen the tube, apply threading and face of any edge for a clean finish on the bottom bracket of the frame

Headset tube MACHINE

a reaming system that widens the tube to make head cups, steering wheel, and forks fit perfectly onto the frame

Bicycle fork preparation machinery

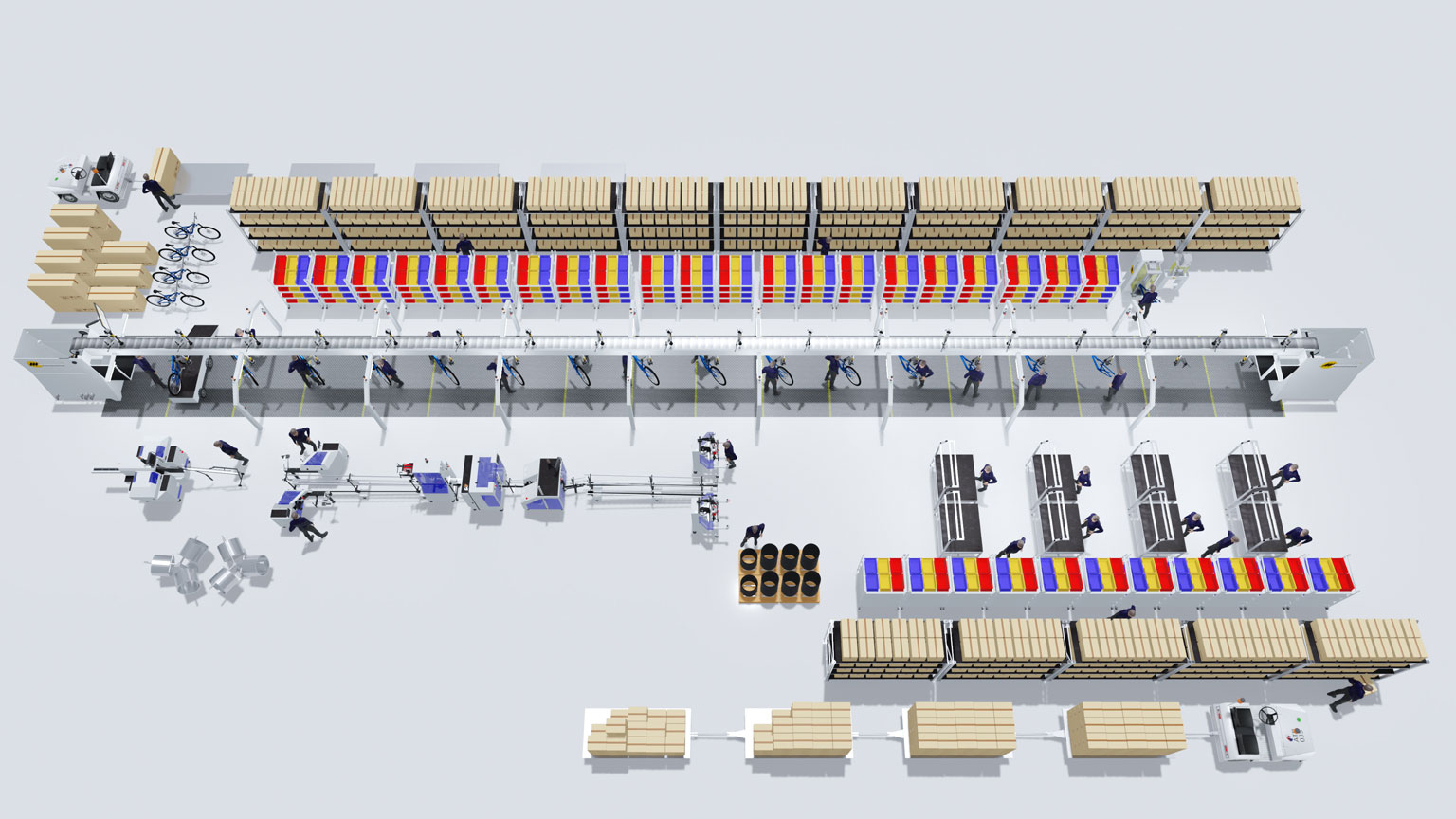

Mini factory, full factory layouts

We can help you create the perfect factory, Combining both wheel and assembly machinery. For an accurate, ergonomic and efficient factory line.