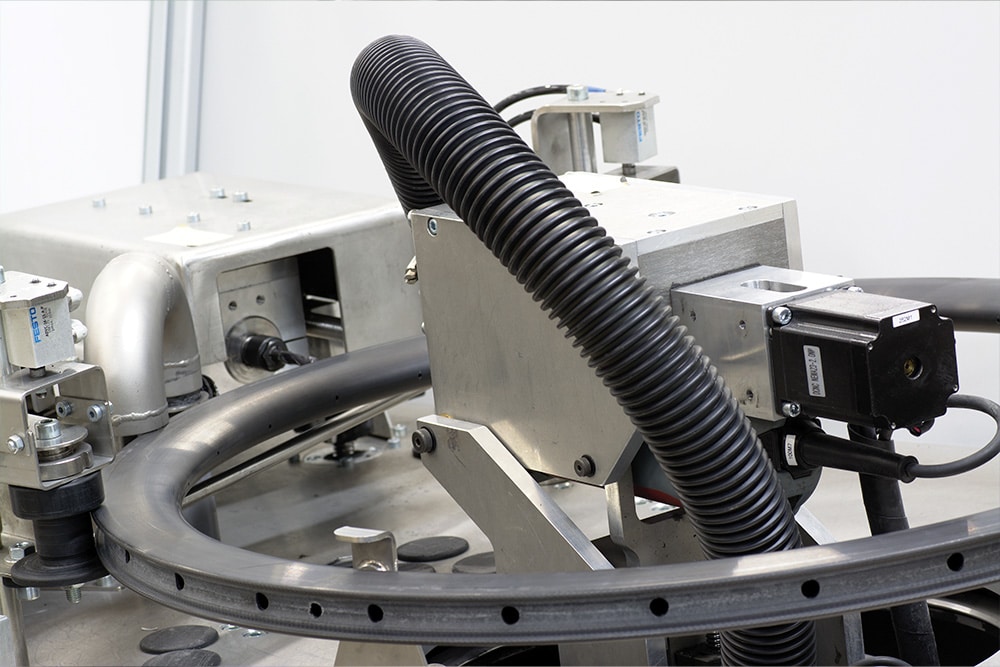

Holland Mechanics Recently Acquired The Rim Drilling Machine From TSG Group. This High-End Rim Drilling Station Is Designed To Accurately Drill Spoke And Valve Holes Into Carbon Rims And Other High-End Rims. The High-End Rim Drilling Station Is Capable Of Drilling The Spoke Holes Into The Rim From Both The Inside And Outside And Can Even Drill The Valve Holes From The Outside.

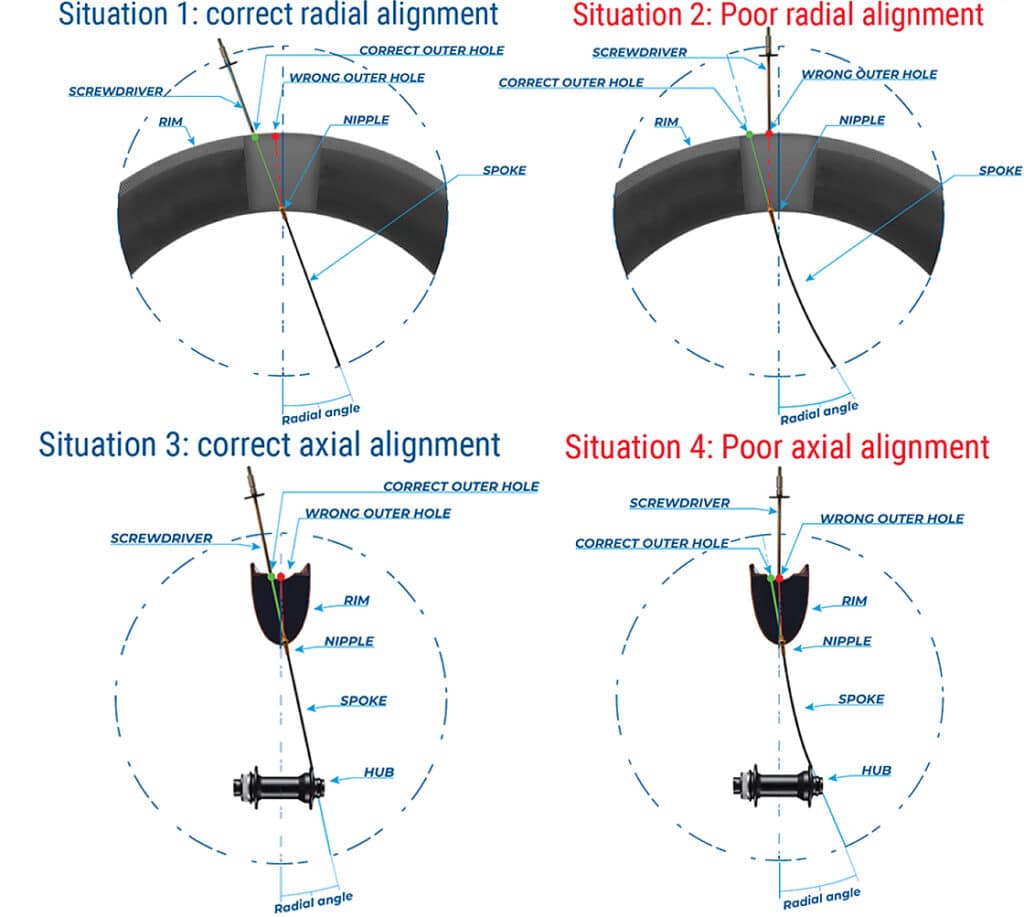

Drill from all possible angles

The rim drilling machine is capable of drilling nipple holes and the valve hole from the outside and nipple holes from the inside. The outer holes can be drilled in an Axial offset and the inner holesin both axial and radial offset. Having the flexibility to drill all holes perpendicular to the spoke angle has a positive effect on the nipple seating and screwdriver engagement, thus the final wheel quality

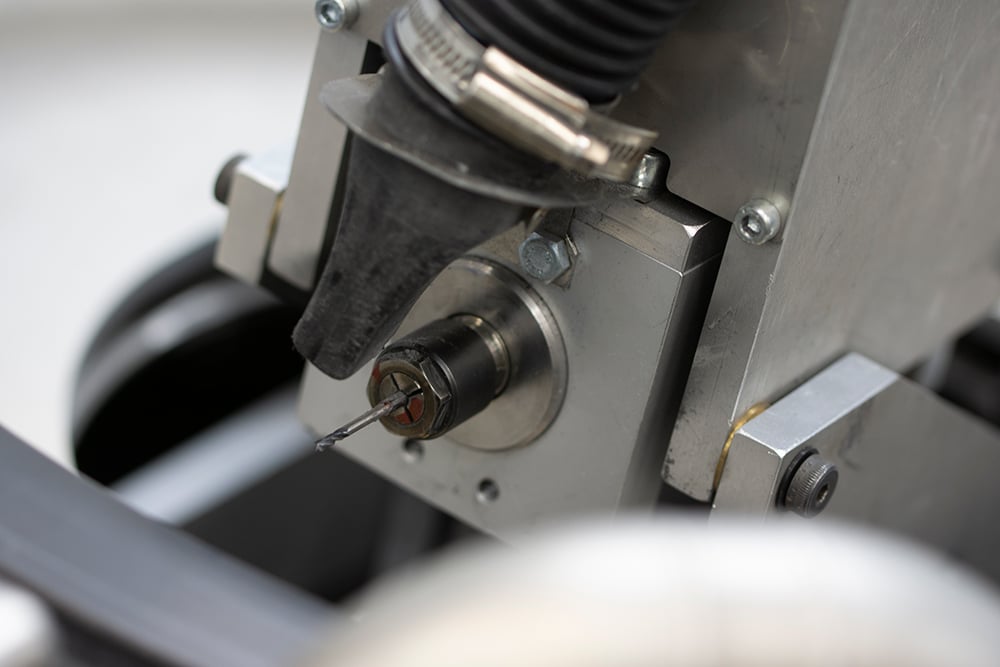

In-Build vacuum cleaner

To make the machine as safe as possible, the drilling process takes place in a closed compartment. In addition, there is a in-build vacuum cleaner positioned at the drilling process to to drain all carbon dust/fibers. This has a beneficial effect on cleaning and ensures that the rims will be clean after drilling the holes.